Reaction Plan Manager++ Analysis Tools

Reaction Plan Manager++ Analysis Tools

Analysis Tools

The key to developing a reaction plan is the Dimension Item. How they are organized and configured determine the instructions the

operator sees. They are used as the building blocks of a Reaction Plan. Dimension Items contain measurement data, statistic

calculations, correction calculations, operator instructions and evaluation rules. When you insert a Dimension item in your document you

will configure the parameters and place it in the proper location. You have complete control over how the calculations are performed,

instructions the operator sees and the rules used for evaluation. They are extremely powerful and easy to configure.

Rules

As data flows into and

correction calculations are

performed. The results

are compared against

rules for violations. If a

Rule violation occurs than

an action associated with

that rule is triggered. The

reaction would be an

instruction to the operator.

Rules

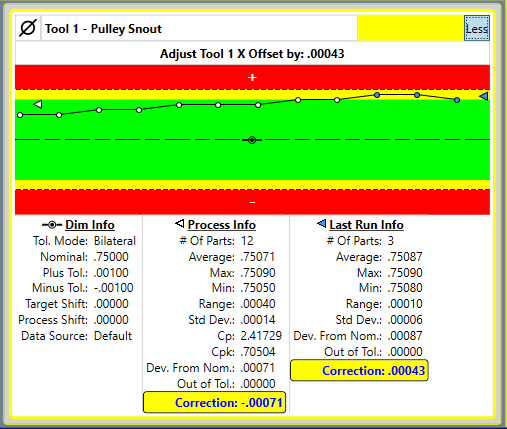

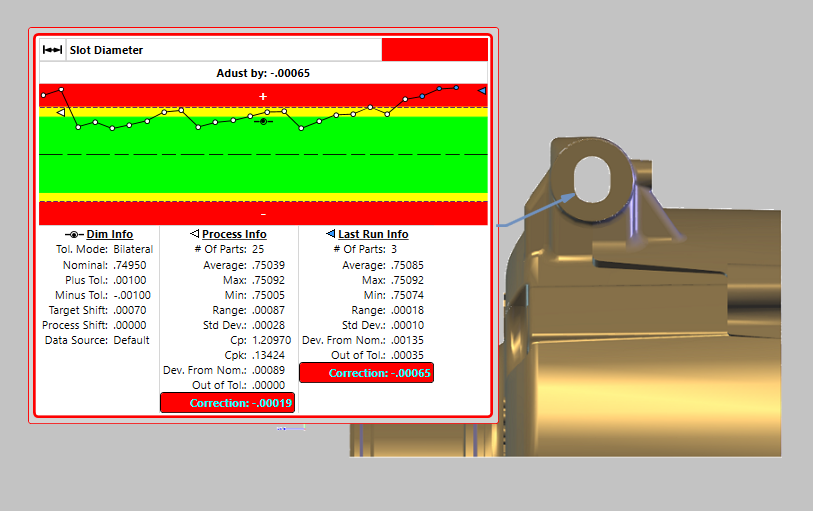

Statistics Calculations

Statistics are an important part of process control. They are used in the

calculations to compute the operator actions. Two types of statistics are

used Process and Last Run. The Process statistics are calculated using all

the data in the Dimension Item. They include the average, maximum,

minimum, range, standard deviation, Cp and Cpk. The Last Run statistics

are based from a smaller number of parts and represent the last data points

entered into the Dimension Item (last measured parts). They include the

average, maximum, minimum, range and standard deviation.

Correction Calculations

Correction calculations are used to adjust the manufacturing process. They

represent the exact amount the operator needs to target the process. You

can apply a scale factor to control the adjustment magnitude and direction.

For example the Last Run Deviation from Nominal is .005. You know from

experience the machine adjustment should only be half that amount. You

can apply a .5 scale factor so the Last Run Correction would be .0025.

Process Targeting

Process targeting is the act of

adjusting your machine to

consistently produce parts that

are in specification. The target

is usually based on print

dimensions. Sometimes, for

manufacturing purposes the

target is shifted. This could be

to extend tool life or simply

minimize adjustments. When

configuring a Dimension item

you can apply a target shift to

move the target anywhere you

want. This gives you a way to

optimize the manufacturing

process while maintaining part

quality. With Reaction Plan

Manager++ it’s all about the

process.

Process Targeting

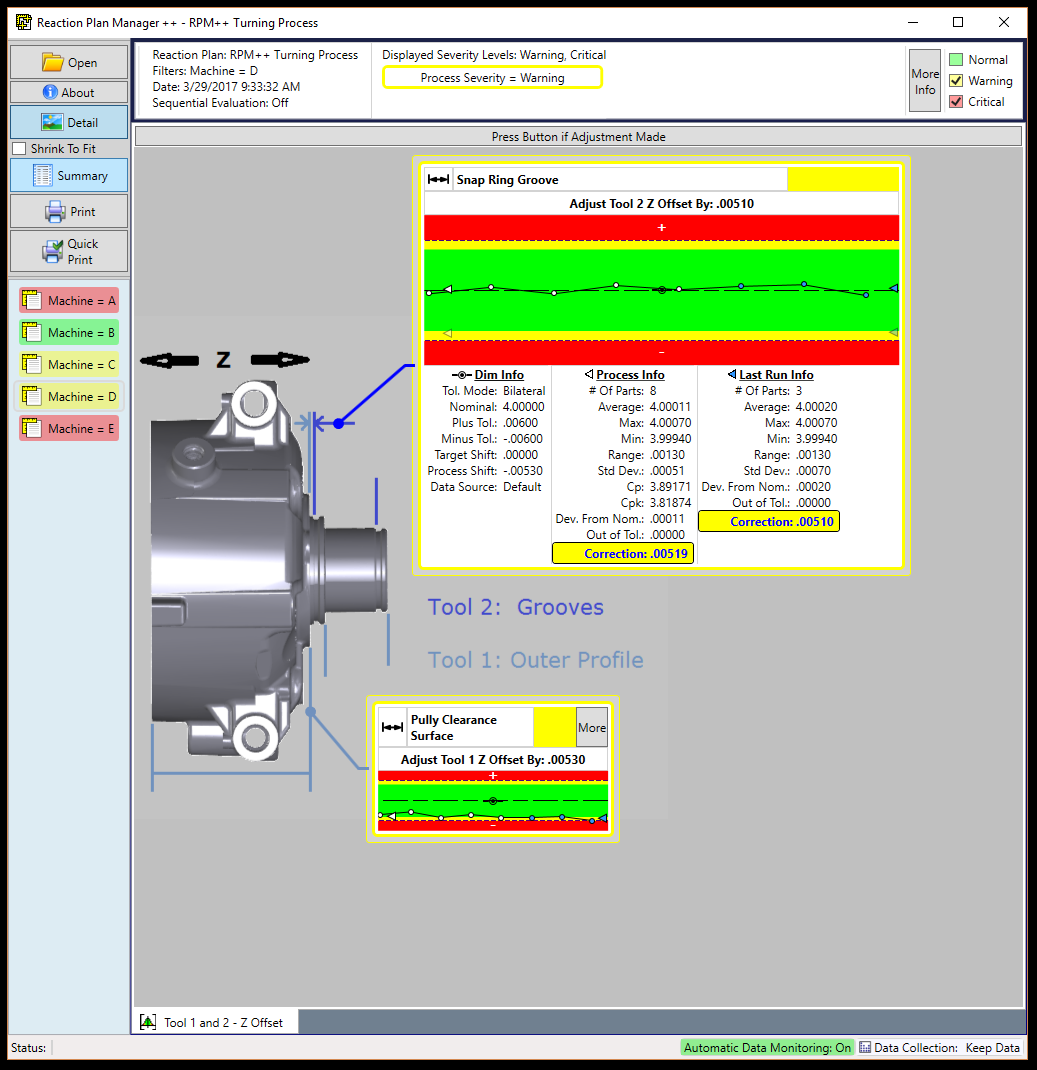

Links

Connect dimension items together to share data. By linking Dimension

items you can apply the correction from one dimension to another. You

control when and what data is shared. For example you know that the

adjustment amount of tool 1 must be added to tools 2 and 3 if tool 1 is

adjusted. You can link the Dimension items representing tools 1 to tools 2

and 3. When an adjustment is triggered for tool 1 the correction amount is

automatically applied to tools 2 and 3. The links would cause the operator to

adjust tools 1, 2 and 3 all because tool 1 required an adjustment. Why is

this important? You can calculate ALL the adjustments in one report. A very

powerful feature.

Links

Sequential Evaluation

Some manufacturing processes require the machine be adjusted in a

specific order to produce quality parts. The operator must first adjust A

before adjusting B. You can force the operator to follow a procedure in the

Reaction Plan by turning on Sequential Evaluation. After the measurement

data is processed Sequential Evaluation forces the Dimension items to be

evaluated in order. The first Dimension item in the list with a warning or

critical severity level is displayed. The operator must follow the instruction

and fix the problem before the rest of the Reaction Plan is evaluated.