Bolt Pattern Analysis

Bolt Pattern Analysis

Introduction

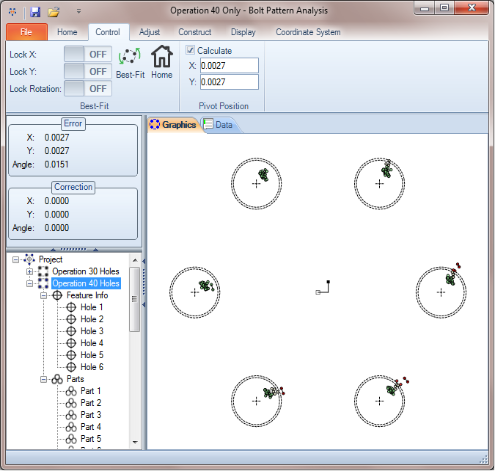

The Bolt Pattern Analysis (BPA) software provides tools to

evaluate the process of machining holes and pins. Within

seconds you can determine how well your machine is targeted

and how to fix it if adjustments are required. The software uses

statistical indicators to evaluate the current process and

best-fit tools to calculate machine adjustments. Using the

project explorer you can analyze data from one machine, two

machines or all the machines in the manufacturing process

from a single project. The software is ideal for CNC machines,

transfer lines and other production equipment.

How It Works

You build a project from part data. Then analyze the

manufacturing process using the graphical output, statistical

indicators and best-fit tools. It is simple to build a project. You

can enter data manually, import data from excel or use the

Data Collector. The Data Collector is a powerful feature. It

automates the extraction of data from software packages like

QC-CALC Real-Time, CMM Software and other data

sources. With a click of a button the Data Collector reads data

from all the data sources and builds your project automatically.

Key Benefits

- All machine correction calculations use data from multiple parts giving you accurate process adjustment information.

- Quickly identify root cause of machine problems like tooling, fixturing, targeting etc.

- Determine if the calculated machine corrections will improve the process capability before machining additional parts.

- Analyze data from multiple operations (machines) in a single project.

- Easy to use - Whether you are a process engineer, quality engineer or inspector on the shop floor, the software is designed to be used throughout the manufacturing process.

- Cost savings through a reduction in machine downtime and scrap