Reaction Plan Manager++ Shop Floor View

Reaction Plan Manager++ Shop Floor View

Introduction

The Reaction Plan Manager®++ software is designed to guide

machine operators through the process of adjusting their machine

to prevent machine down time. It provides current process information.

It does not provide a history of events. What happened last shift?

Did the operator measure his parts? How many events occurred over

that time? Did the operator make the machine corrections as outlined

in the reaction plan? Based on a history are there any features that

need attention by engineering? The Reaction Plan Manager ®++ Shop Floor View

software is used by management and engineering to answer these types of

questions. It displays current process status information and provides

tools to view a history of events with data analytics.

How It Works

While your machine operators are measuring parts and using the Reaction

Plan Manager®++ software to get machine adjustment instructions the results

of each analysis are stored in a database. The Reaction Plan Manager++

Shop Floor View software will use the captured data to show the status of

each process (machine) in a dashboard and provide tools to drill down into

the data to get detailed report information.

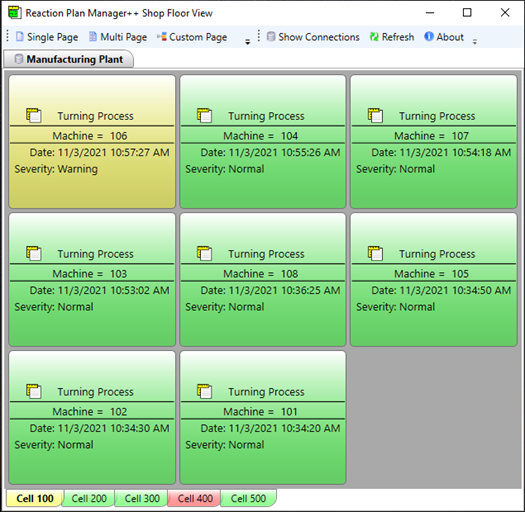

Process Status Dashboard

Displays current Process Status information. The dashboard contains process

status buttons. Each button identifies the process (machine) and has a

background color of green, yellow, or red which is normal, warning, and critical

severity, respectively. How those buttons are grouped are customizable and organized

by date. At a glance you can identify which process is having problems and the last

time data was analyzed for each. A click of a button lets you drill down into

the event data.

Used as a Management Tool

A manager can see exactly what process control information the operator saw

at any given time for each machine. Using this information, he/she can

determine if parts are being measured to control the process and if the operators

are using the information to make machine corrections. The data analytics will

help identify where to allocate engineering resources.

Used as an Engineering Tool

Data analytics give engineers tools to quickly pinpoint features that require

attention. Detailed process information is provided to help diagnose and resolve

process problems.

Benefits

- Better allocation of resources. Understanding what happened in the past makes it easier to plan for the future.

- Cost savings from a reduction in engineering hours supporting the shop floor, machine down time and scrap.